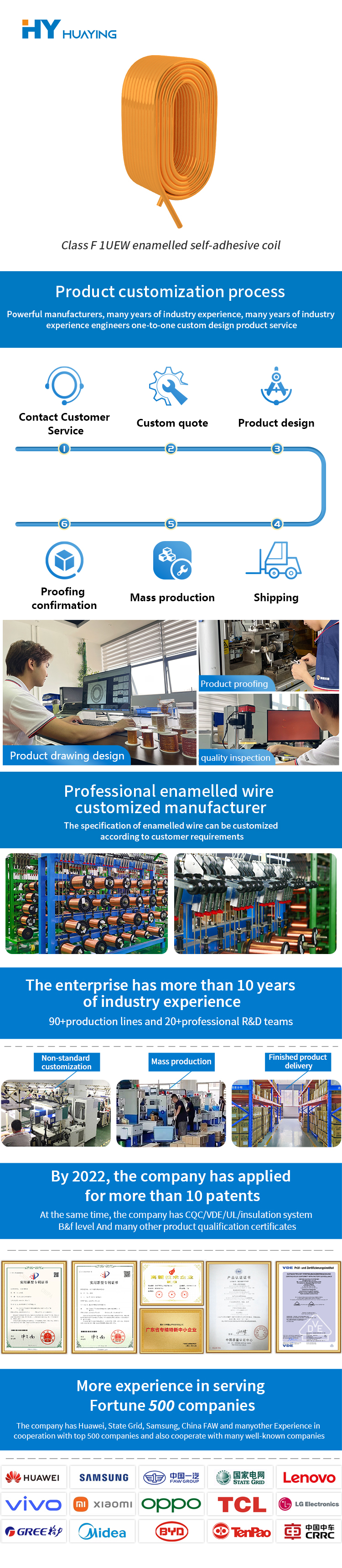

Zazzabi da juriya na matsin lamba don haɓaka ingantaccen aiki F-class 1UEW enamelled mai ɗaukar nauyin coil masana'antar lantarki ta lantarki

Sunan samfur: F-class 1UEW enamelled coil mai ɗaure kai

Sunan samfur: F-class 1UEW enamelled coil mai ɗaure kai

·Wayar enamel mai ɗaure kai (waya mai ɗaure kai), wacce kuma aka sani da waya mai narkewa, tana da ƙarin fenti mai ɗaure kai a saman wayar da aka yi mata.

·Yana da matukar wahala a ƙirƙira sarƙaƙƙiya masu siffa maras ƙarfi da ake amfani da su a farkon TVs da wasu ƙananan injuna tare da wayoyi masu ƙyalli na yau da kullun. Tsarin kera irin wannan nau'in coil na ƙulla ya kasance na musamman. Da farko, dole ne a sarrafa iska guda ɗaya kuma a samar da ita, sannan kowane nau'in iska ya zama iskar sulke. Hanya guda ɗaya da aka yi amfani da ita ita ce yin amfani da abin ɗamara a saman farfajiyar wayar da aka yi masa gyaran fuska don gyara shi a kan gyaɗa, sannan a gasa a siffata shi. Tsarin jujjuyawar motsi ya sami sakamako mai kyau na tattalin arziki. Ana amfani da shi sosai a cikin mahimman abubuwan samfuran lantarki kamar injina maras tushe, coils masu ɗaure kai, micro-motors, masu wutar lantarki, firikwensin, da abubuwan lantarki. Haɓaka kayan aikin armature da na'urar wuta.

Tsarin jingina:

Lambun mai ɗaure kai da aka lulluɓe akan saman waya mai ɗaure kai zai iya haifar da mannewa ta hanyar yanayin zafi mai zafi ko abubuwan kaushi na sinadarai.

Haɗin zafi mai girma / zafi:

Ana iya haɗa duk yadudduka na Elektrisola ta hanyar dumama. Za a iya dumama wayar kai tsaye da iska mai zafi yayin da ake juyar da ita, ko kuma za a iya dumama nadar rauni ta cikin tanda, ko kuma a yi amfani da na'urar ta halin yanzu a kan nada bayan an gama iskar. Ka'idar duk waɗannan hanyoyin ita ce dumama na'urar da ke jujjuyawa zuwa zafin jiki kaɗan sama da yanayin narkewar maɗaurin kai, ta yadda maɗaurin kai ya narke kuma ya haɗa wayoyi tare. Air-ta hanyar haɗin gwiwa yana da fa'idar rashin buƙatar tsarin haɗin gwiwa na biyu bayan iska. Wannan hanyar tana da tsada kuma ana amfani da ita musamman don wayoyi masu ɗaure kai tare da girman ƙasa da 0.200mm. Wannan hanya ta zama mafi shahara a cikin 'yan shekarun da suka gabata tare da haɓaka nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan yanayin zafi mai tsananin zafi.

Haɗin tanda:

Haɗin tanda yana cika ta hanyar dumama murfin rauni. Har yanzu ana ajiye nada a kan na'ura ko kayan aiki yayin da ake yin iska, kuma ana yin dumama gaba dayan nada a cikin tanda a daidai lokacin da ya dace, sannan a sanyaya. Lokacin dumama ya dogara da girman nada, yawanci mintuna 10 zuwa 30. Rashin lahani na haɗin tanda shine tsawon lokacin haɗin kai, ƙarin matakan tsari, da yuwuwar buƙatu mafi girma akan adadin kayan aikin rauni.

Electrobonding:

Ana yin hakan ne ta hanyar amfani da wutar lantarki zuwa nada da aka gama da kuma samar da zafi ta hanyar juriyarsa don cimma daidaitaccen zafin haɗin gwiwa. Wutar lantarki da lokacin ƙarfafawa sun dogara da girman waya da ƙirar coil don haka ana buƙatar haɓakawa ta gwaji don kowane takamaiman aikace-aikacen. Wannan hanya tana da abũbuwan amfãni na sauri sauri da kuma uniform rarraba zafi. Yawancin lokaci ya dace da waya mai ɗaure kai tare da girman diamita na waya fiye da 0.200mm.

Haɗin mai narkewa:

Ana iya kunna wasu yadudduka masu ɗaure kai ta amfani da takamaiman abubuwan kaushi yayin aikin jujjuyawar nada. Lokacin da ake juyewa, ana amfani da jika mai narkewa ("rigar winding") don tausasa shimfiɗar mai ɗaure kai. Wannan tsari yana buƙatar yin amfani da kayan aiki don riƙe coils a wuri, kuma ana haɗa kullun tare bayan daɗaɗɗen ya bushe. Sa'an nan ya kamata a yi zafi a cikin tanda don sake zagayowar guda ɗaya don ƙafe sauran kaushi da kuma kammala aikin gyaran Layer mai ɗaure kai don ingantaccen haɗin gwiwa. Idan akwai sauran sauran sauran ƙarfi a cikin nada, zai iya haifar da nada ya gaza bayan dogon lokaci.

1-300x300.jpg)